In the cosmetic and medical skincare industries, the transdermal absorption rate of active ingredients, product stability, and user experience directly determine the product's efficacy and market competitiveness. Medical aesthetic skincare products often contain complex formulations such as high-concentration active ingredients, nano-carriers, and liposome encapsulation systems, requiring extremely high demands on production technology.

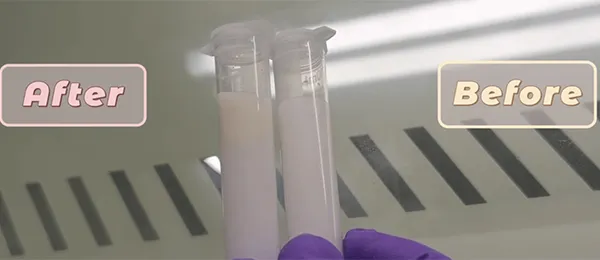

ATS successfully applies high-pressure homogenization technology across the research, development, and production processes for medical aesthetic skincare products. Providing the industry with precise and efficient nano-emulsification, dispersion, and carrier formulation solutions, ensuring a seamless transition from laboratory research to industrial-scale production and quality control.

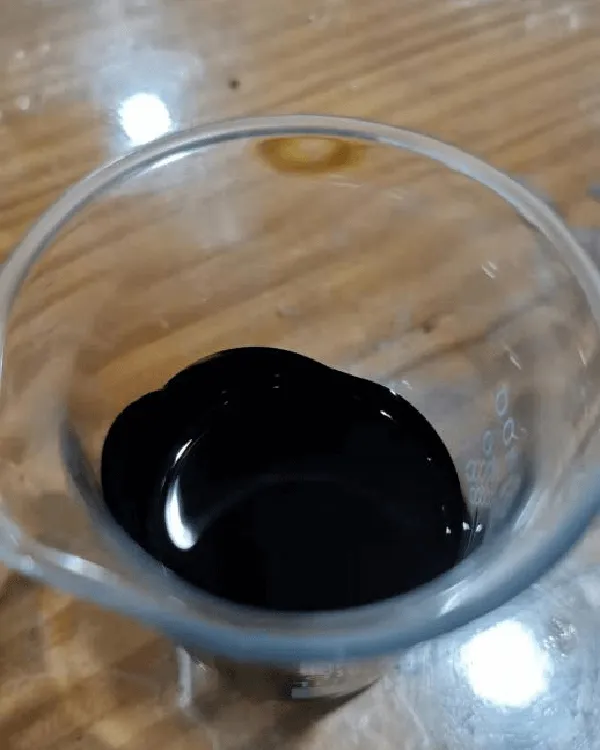

Collagen production line

Let us help you find the right nano-processing equipment to support your R&D, scale-up, and production needs.