High Pressure Homogenizer & Liposome Extruder for Pharmaceutical

In the development of new drug formulations, the solubility, bioavailability, and delivery efficiency are key factors influencing product efficacy. Nanotechnology has become a revolutionary solution for poorly soluble drugs, targeted delivery, and advanced vaccine systems. High-Pressure Homogenizer (HPH) and Micro-Jet Homogenizer (Microfluidic Homogenizer) are the global standards for industrial nanoemulsion, suspension, and liposome formulation.

Key Challenges & Solutions

- Nanoemulsions and Submicron Emulsions

Efficiently solves the delivery of poorly soluble drugs. Transforming water-insoluble drugs into intravenous fat emulsions or oral nanoemulsions significantly improves their bioavailability. ATS high-pressure homogenization produces nano-sized aggregated dispersion, ensuring stable emulsions for oral and injectable use.

- Nanocrystallization of Suspensions

High-pressure homogenizer processes drug crystal suspension formulation by reducing API particles to nanoscale particles. This will enhance the dissolution rate and effectively prevent protein-based drugs from forming aggregates during storage, reducing the risk of immunogenicity and ensuring the safety of biological agents.

- Liposomes and Multilamellar Vesicles

Produce liposomes as drug carriers, enabling sustained-release and targeted delivery. Liposome extruder offers precise control over particle size, lamellarity, and encapsulation efficiency, ensuring high standards of complex formulations.

- Lipid Nanoparticle (LNP) Delivery Systems

As core production equipment for mRNA vaccines and drug delivery, ATS microfluidic homogenizer enables the precise and controllable molecular self-assembly of lipids and nucleic acids. This provides uniform-sized LNPs particles with high encapsulation efficiency, enhancing the drug delivery system performance and stability.

Recommended Products for Pharmaceutical and Medical Products

- Full temperature control system to maintain biological activity

- Variable flow control system to flexibly adjust flow rates

- GMP-compliant and CE-certified

- Flexible customization options for PLC, explosion-proof, and sterile standards

- Four-layer overpressure protection ensures operational safety

- Offers high scalability from laboratory to industrial scale (max flow rate of 4000 L/H)

- Reduce particle size to the nano-level

- Precise control over particle dispersion

- More uniform-sized and stable results

- Enabling high-pressure operation (up to 3000 bar)

- Customized large-sized multi-layer plates (e.g., 90mm/142m) to increase processing speed and yield

- Can be integrated with manual pumps, electric pumps, high-pressure homogenizers, or industrial air pumps, supporting applications from laboratory to industrial-scale processing

- Made of 316L stainless steel and supports Clean-in-Place and Sterilize-in-Place (CIP/SIP), meeting sterile production standards

- Integrated jacketed temperature control system to ensure precise temperature control during extrusion, ensuring biological activity and batch consistency

Cases

-

Asceptic Inhalator Production Line

Asceptic Inhalator Production Line

-

Suspension Formulation Line

Suspension Formulation Line

-

Liposomal Drug Production Line

Liposomal Drug Production Line

Experimental Cases

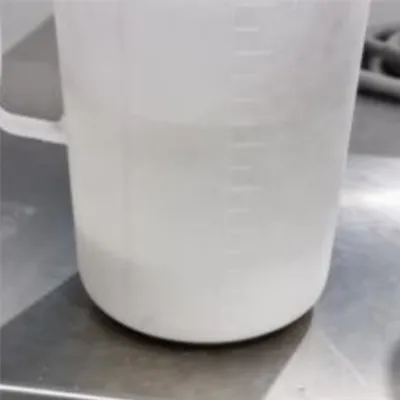

Aluminum Magnesium Carbonate Suspension

ATS high-pressure homogenizer with 5 cycles under high-pressure and low-temperature conditions

- Experimental objective

Particle size after dispersion is D90<1.5um

- Experimental results

Visual observation

After dispersion, the sample became more viscous and less fluid.

Particle size analysis

After dispersion, the D90 particle size was reduced from 8.439μm to 1.474μm, meeting the target size.

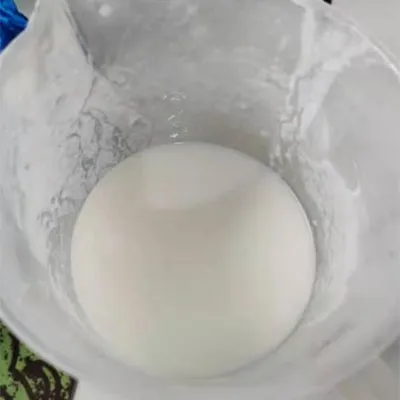

Simethicone Emulsion Preparation

Preparation process

The first step in preparing simethicone emulsion is to create the pre-emulsion by mixing the raw materials, emulsifier, thickening agents, and others in a specific order and proportion. The pre-emulsion has relatively large particles and weak defoaming ability, so the initial process is to reduce the particle size. In recent years, using high-pressure homogenizers has become preferred, since the conventional filter membrane yields limited product and higher costs.

Challenges

The common problem is incomplete emulsification, leading to a layer of oil floating on the surface after homogenization.

Solutions

ATS uses a special homogenizing valve that solves the floating layer of oil and produces emulsion particles within the required size range.

Experimental results

- Particle size before homogenization is D50=36.93µm

- Particle sizes after homogenization are D50=4.442µm and D90=10.35µm, very close to D50=4.402µm and D90=10.34µm

The homogenized emulsion remained stable without phase separation after 5 days.

Homogenizers are used to achieve appropriate particle sizes for simethicone emulsions, and precise pressure control is essential to ensure high-quality emulsions. ATS homogenizers use specialized homogenizing valves that maintain stable low-pressure conditions and ensure consistent particle-size control. In addition, the raw materials and excipients used in the sample significantly affect the initial emulsion preparation; therefore, it is important to select a suitable high-pressure homogenizer according to your specific process requirements.

Microcrystalline Cellulose (MCC) Pulverization Preparation

- Experimental object

Microcrystalline Cellulose (MCC)

- Equipment

ATS high-pressure homogenizer

- Experimental objective

To grind the Microcrystalline Cellulose’s particles into fine, smaller particles

- Experimental process

Pretreatment: The solid content of the raw cellulose is quite high. After dilution with water, the solid content was reduced to 6% and was then used as the experimental sample.

The ATS high-pressure homogenizer is equipped with a specialized grinding valve seat, through which the cellulose will pass and be pulverized, and the experiment was conducted with online temperature control.

Experimental results

Asceptic Inhalator Production Line

Asceptic Inhalator Production Line  Suspension Formulation Line

Suspension Formulation Line  Liposomal Drug Production Line

Liposomal Drug Production Line

Before homogenization

Before homogenization After low-pressure homogenization

After low-pressure homogenization After high-pressure homogenization

After high-pressure homogenization Before homogenization

Before homogenization After low-pressure homogenization

After low-pressure homogenization After high-pressure homogenization

After high-pressure homogenization