In the fields of new energy and advanced materials, the preparation and processing of materials such as graphene, carbon nanotubes (CNTs), metal oxides, Pt/C catalysts, PEDOT conductive polymers, MLCC/CMP slurries, and nanocellulose place extremely high demands on process technology, nanostructure control, dispersion stability, and production efficiency directly influence the performance and reliability of the final products.

ATS homogenizers deliver high-performance solutions, providing efficient dispersion and stabilization for critical applications. Covering the entire chain from laboratory research and development to large-scale production, helping global companies develop more competitive and innovative new-energy materials.

Carbon Nanotube (CNT) Production Line

Carbon Nanotube (CNT) Production Line  Double-Walled Carbon Nanotube (DWCNT) Production Line

Double-Walled Carbon Nanotube (DWCNT) Production Line The surface energy of 3–5 nm platinum nanoparticles is extremely high, causing strong tendencies toward agglomeration, and the properties of the catalyst slurry significantly influence the structure formation of the catalyst layer. Therefore, the dispersion method used in preparing the catalyst slurry is critical for producing high-performance membrane electrode assemblies (MEAs).

Equipment

Laboratory high-pressure homogenizer

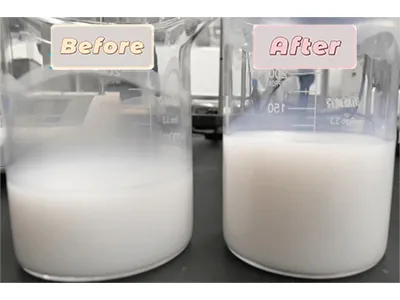

A comparison of the platinum carbon catalyst slurry before and after dispersion shows that the degree of precipitate has significantly decreased after dispersion.

The particle size of the dispersed slurry was measured by a laser particle size analyzer. The particle size distribution was between 202.3nm–444.4nm, with an average of particle size of 290.5nm.

Before dispersion

Before dispersion  After dispersion

After dispersion

Experimental results

Visual observation

The metal oxide's appearance showed no significant visible change before and after pulverization. After being left aside for a certain duration, the higher pressure resulted in slower stratification of the sample.

Particle size measurement

The particle size of the metal oxide was significantly reduced after being pulverized by the high-pressure homogenizer. The average particle size reduced from 12.05μm to 303nm, meeting the experimental expectations.

Let us help you find the right nano-processing equipment to support your R&D, scale-up, and production needs.