In fine chemical manufacturing, product consistency and process stability are key factors determining both performance and market competitiveness. Fine chemicals such as pigments, electronic chemicals, additives, and specialty polymers require high precision control in particle size and dispersion uniformity. ATS homogenization technology provides high-precision, efficient nano-dispersion, emulsification, and homogenization solutions for fine-chemical preparation and optimization. This will ensure a seamless transition from laboratory-scale to industrial-scale production.

Double-Walled Carbon Nanotube (DWCNT) production line

Double-Walled Carbon Nanotube (DWCNT) production line  Carbon Nanotube (CNT) production line

Carbon Nanotube (CNT) production line n-Alkanes are primarily used as the intermediate mono-olefins for manufacturing Linear Alkylbenzene (LAB). The light wax product obtained by molecular sieve adsorption separation and dewaxing has an n-alkane content of over 96%, while the light wax from isopropanol-urea dewaxing contains over 90%. The aromatic hydrocarbon content of both is below 1%. Light wax is mainly used as an intermediate mono-olefin in the manufacture of LAB and can also serve as a raw material for plasticizers, chlorinated paraffins, and petroleum proteins. This experiment will emulsify the n-alkane emulsion to improve product performance.

Using ATS micro-jet homogenizer to prepare a nano silicon dispersion

In this experiment, ATS nano disperser is used to disperse nano silicon powder in an aqueous medium, forming a highly dispersed, uniform, and stable nano silicon aqueous slurry with higher activity and ease of incorporation.

After the nano silicon slurry was dispersed with ATS nano disperser, the D90 particle size decreased from 14.38μm to 209.8nm.

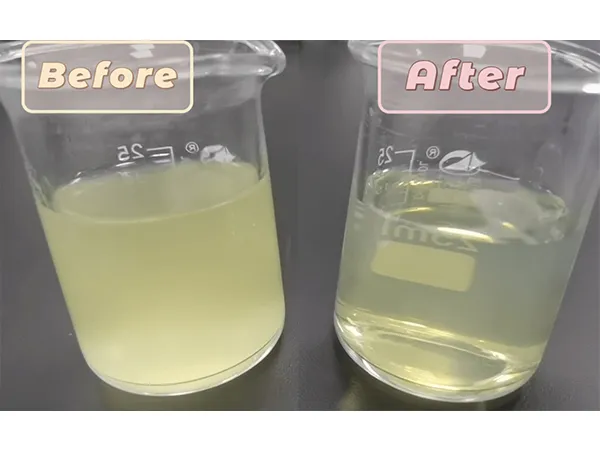

Before emulsification

Before emulsification After emulsification

After emulsificationExperiment results

Visual observation

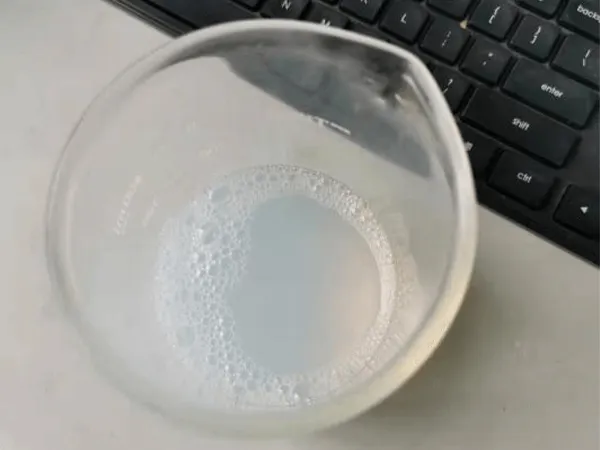

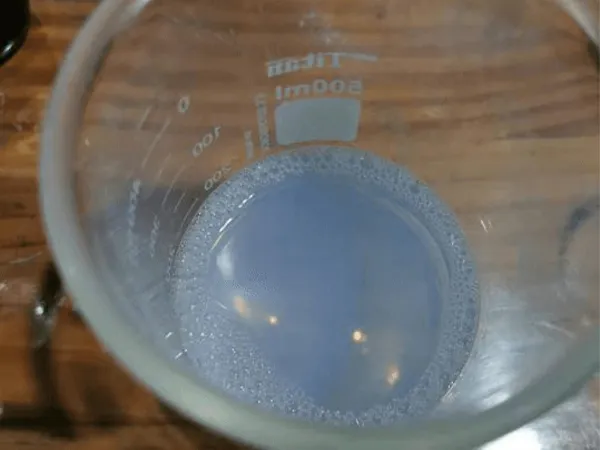

After emulsification, the menthol solution became significantly clearer and showed a slight bluish opalescence.

Particle size observation

After emulsification with the ATS high-pressure homogenizer, the average particle size of the menthol solution was reduced from 98.9 nm to 35.2 nm, while the D90 particle size decreased from 190.6 nm to 82.8 nm, meeting the client's requirements.

Let us help you find the right nano-processing equipment to support your R&D, scale-up, and production needs.