ATS jacketed liposome extruder is professional equipment for liposome and nanoparticle preparation for laboratory and pilot-scale productions. The extruder’s core feature lies in the integrated jacketed temperature-control system, ensuring precise and stable temperature throughout the extrusion process. It is particularly suitable for temperature-sensitive samples.

| Models | |||||

|---|---|---|---|---|---|

| Max. Sample Size (ml) | 1 | 10 | 100 | 500 | 800 |

| Min. Sample Size (ml) | 0.1 | 2 | 10 | 100 | 200 |

| Power Mode | Hand drive/compressed air | Compressed air | Compressed air | Compressed air | Compressed air |

| Thermo Control | Water bath heating | Jacketed | Jacketed | Jacketed | Jacketed |

| Working Temperature (℃) | 5-80 | 5-80 | 5-80 | 5-80 | 5-80 |

| Filter Membrane Diameter (mm) | 19 | 25 | 47 | 90 | 90 |

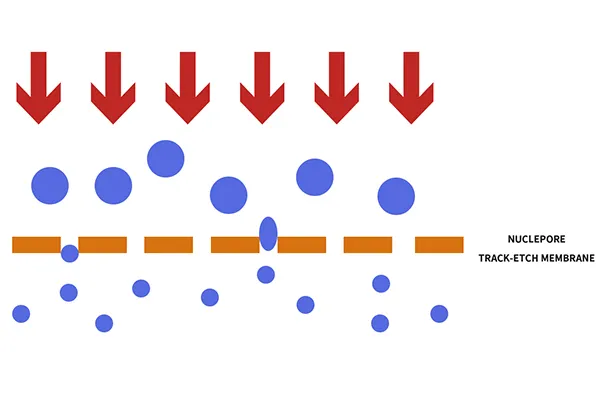

The multilamellar liposome suspension is repeatedly extruded through the polycarbonate membranes with predefined pore sizes to produce unilamellar liposomes and nucleic acid. The multi-compartment samples are forced through the membranes by extrusion force to form a uniform, smaller liposomes ranging from 50–1000 nm.

Let us help you find the right nano-processing equipment to support your R&D, scale-up, and production needs.