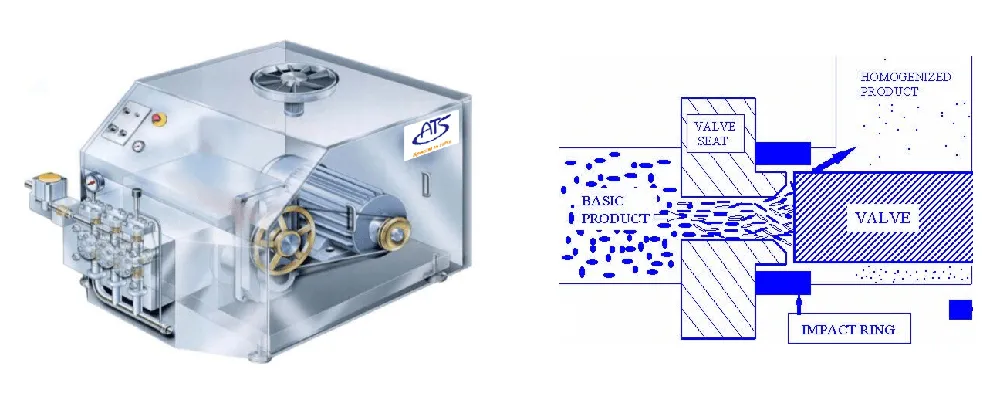

ATS industrial high-pressure homogenizer is engineered for continuous high-pressure operation with a capacity of up to 4000 L/H at 1500 bar. It ensures high-efficiency homogenization and stable operation with four-layer safety protection, PLC control, and optional explosion-proof and aseptic customization. It is ideal for pharmaceutical, food & beverage, cosmetics and advanced material industries.

| Models | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Rate (L/H) | 100-150 | 200-250 | 500-600 | 250 | 600 | 1000 | 1000 | 1600 | 2000 | 2000 | 3200 | 4000 |

| Working Pressure (bar) | 0-1500 | 0-1000 | 0-1000 | 0-1500 | 0-1500 | 0-1000 | 0-1500 | 0-1000 | 0-1000 | 0-1500 | 0-1000 | 0-1000 |

| Power (kW) | 11 | 11 | 18.5 | 18.5 | 30 | 30 | 75 | 75 | 75 | 110 | 110 | 132 |

| Weight (kg) | 689 | 689 | 1265 | 1265 | 2400 | 2400 | 2400 | 2500 | 2500 | 2800 | 3900 | 4000 |

| Dimensions (mm) | 1600*950*1160 | 1600*950*1160 | 1710*1040*1155 | 1710*1040*1155 | 2060*1570*1330 | 2060*1570*1330 | 2060*1570*1330 | 2060*1570*1330 | 2060*1570*1330 | 2780*1530*1430 | 2780*1530*1430 | 2780*1530*1430 |

The industrial-scale homogenizer uses the reciprocating motion of a plunger pump to pressurize the product and force it through an adjustable homogenizing valve. The product undergoes intense compression and passes through a narrow gap at high speed, generating cavitation, turbulence and shear forces that break down large particles and droplets into uniform, stable dispersions.

GMP standard vaccine workshop

GMP standard vaccine workshop  Manufacturing workshop for E. coli cell disruption

Manufacturing workshop for E. coli cell disruption  Suspension processing workshop

Suspension processing workshop  Chemical material production line

Chemical material production line Let us help you find the right nano-processing equipment to support your R&D, scale-up, and production needs.