ATS pilot-scale micro-jet homogenizer bridging the gap between laboratory research and industrial production. This homogenizer operates stably at pressures up to 40,000 psi, with diamond interaction chamber (DIXC) technology to achieve precise nano-level homogenization with ultra-narrow particle-size distribution, perfectly reproducing the lab-scale data. Its adjustable flow rate supports scale-up production, parameter optimization, and designed for mid to small-batch production, while reducing cost and risk during industrialization.

| Models | ||

|---|---|---|

| Flow Rate (L/H) | 30 | 50-60 |

| Min. Volume (ml) | 200 | 300 |

| Max. Working Pressure | 207 MPa/2070 bar/30,000 psi | 207 MPa/2070 bar/30,000 psi |

| Chamber Configurations | Main 200um + auxiliary 75um Y/Z-type DIXC | Main 400um + auxiliary 75um Y/Z-type DIXC |

| Operation Mode | 380V hydraulic | 380V hydraulic |

| Power (kW) | 7.5 | 11 |

| Dimensions (mm) | 1400*450*475 | 1600*840*1520 |

The fluid sample is rapidly forced through the narrow gaps within the dispersion unit under high pressure. The sudden pressure drops generate extremely high-speed velocities, leading to intense turbulence, cavitation, shear forces, and jet flow, which break apart the particles, reducing them into a fine and uniform nano-scale homogeneous state. Furthermore, the hydraulic intensifier power mode can provide a stable pressure of up to 200 MPa.

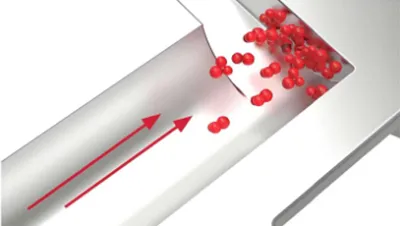

Turbulence

Turbulence is caused by the mutual collisions of sample molecules due to cavitation.

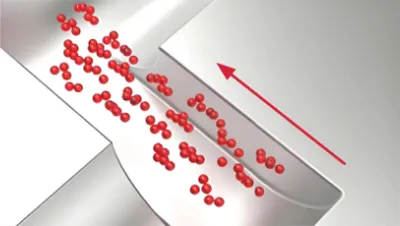

Shearing

Shearing in fluids occurs due to the friction between the molecules and the wall of the dispersion unit, viscosity, etc.

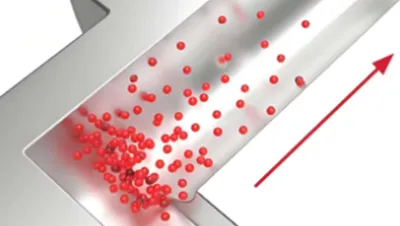

Cavitation

Cavitation refers to the cavities or bubbles created in fluids. If the velocity increases, the cohesive force between molecules and the voids or bubbles in the liquid rapidly collapses, generating a shock wave.

Let us help you find the right nano-processing equipment to support your R&D, scale-up, and production needs.